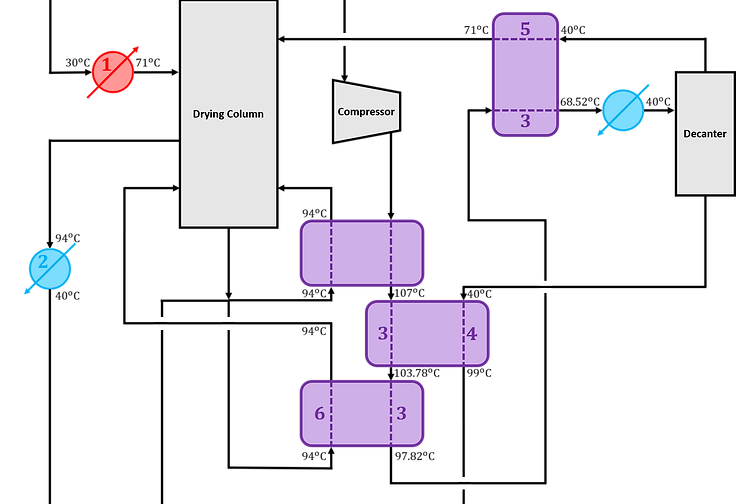

SOLUTION 5

).png)

3''

5

3 4

6 3'

Preexisting

heat exchanger

Heat exchanger (3-4)

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Stream 3

Heat capacity*Mass flowrate

40.3 kW/°C

Heat gained by system

-2700.1 kJ/s

Temperature in

107°C

Temperature out

40°C

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Stream 4

Heat capacity*Mass flowrate

2.2 kW/°C

Heat gained by system

129.8 kJ/s

Temperature in

40°C

Temperature out

99°C

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Heat exchanger

Remaining heat

2570.3 kJ/s

Temperature Hot out

103.78°C

Log mean Temperature

26.89°C

We now seek to find the maximum amount of heat that can be exchanged between stream 3 and stream 4. This maximal amount corresponds to the lowest value of the absolute value of heat gained by the system between stream 3 and 4.

From that we calculate the remaining heat that needs to be removed

And the effective temperature out of Stream 3

Finally, we calculate the log mean temperature using the formula

Cost

Cross sectional area

5.62m²

Costs

5 633£

Variance on cost

±845£

We first calculate the area required for the heat exchanger based on this equation:

where U represents the overall heat transfer coefficient

and Q represents the actual amount of heat tranferred between the two streams above.

We then calculate the cost using the following formula:

%

Heat exchanger (3'-6)

Stream 3'

Heat capacity*Mass flowrate

40.3 kW/°C

Heat gained by system

-2570.3 kJ/s

Temperature in

103.78°C

Temperature out

40°C

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Stream 6

Latent heat of vaporisation

2000 kJ/kg

In stream 6, the substance goes through a phase change whilst remaining at 94°C. We thus use the formula:

We know that the massflowrate is 12kg/s. Additionally, we know that the specific latent heat of vaporisation is 2000kJ/kg.

We thus plug in the numbers and find that

Heat gained by system

240 kJ/s

Mass flowrate

0.12 kg/s

Phase Change

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Heat exchanger

Remaining heat

2330.3 kJ/s

Temperature Hot out

97.82°C

Log mean Temperature

6.34°C

We now seek to find the maximum amount of heat that can be exchanged between stream 3' and stream 4. This maximal amount corresponds to the lowest value of the absolute value of heat gained by the system between stream 3' and 4.

From that we calculate the remaining heat that needs to be removed

And the effective temperature out of Stream 3' which we find to be equal to 97.82 degrees celcius.

Finally, we calculate the log mean temperature using the formula

Cost

Cross sectional area

44m²

Costs

19 370£

Variance on cost

±2 905£

We first calculate the area required for the heat exchanger based on this equation:

where U represents the overall heat transfer coefficient

and Q represents the actual amount of heat tranferred between the two streams above.

We then calculate the cost using the following formula:

%

Heat exchanger (3''-5)

Stream 3''

Heat capacity*Mass flowrate

40.3 kW/°C

Heat gained by system

-2330.3 kJ/s

Temperature in

97.82°C

Temperature out

40°C

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Stream 5

Heat capacity*Mass flowrate

38.1 kW/°C

Heat gained by system

1181.1 kJ/s

Temperature in

40°C

Temperature out

71°C

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

We first calculate the heat gained by the system with the heaters in the plant using the formula:

We then calculate the temperature difference to plug into the equation

We find that

Heat exchanger

Remaining heat

1149.2 kJ/s

Temperature Hot out

68.52°C

Log mean Temperature

27.66°C

We now seek to find the maximum amount of heat that can be exchanged between stream 3'' and stream 5. This maximal amount corresponds to the lowest value of the absolute value of heat gained by the system between stream 3'' and 5.

From that we calculate the remaining heat that needs to be removed

And the effective temperature out of Stream 3'' is found to be 97.82 degrees celcius, using the same formula as previously stated

Finally, we calculate the log mean temperature using the formula and find

Cost

Cross sectional area

49.6m²

Costs

20 825£

Variance on cost

±3 124£

We first calculate the area required for the heat exchanger based on this equation:

where U represents the overall heat transfer coefficient

and Q represents the actual amount of heat tranferred between the two streams above.

We then calculate the cost using the following formula:

%

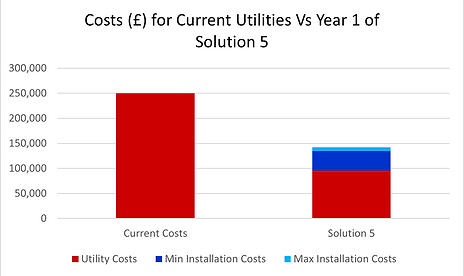

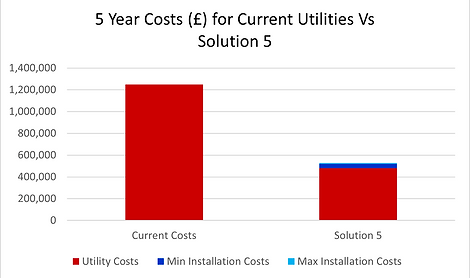

Overall cost

Money saved

723 400 ±6 800£

New total cost

527 000 ±6 800£

Utility cost (per year)

96 000£

Installation cost

45 800 ±6 800£

%

The total cost for this solution is the sum of the costs for utility over 5 years and the installation of the 3 heat exchangers.

Utility costs arise from the requirement for further heating or cooling once a stream has passed through a heat exchanger. If no exchanger is installed on a stream, utility costs for that flow will remain unchanged.

Cooling in this case (requires 2 coolers):

-

The temperature of Stream 2 needs to be reduced by 54.00 °C

-

The temperature of Stream 3 needs to be reduced by 28.52 °C

Heating in this case (requires 1 heater):

-

The temperature of Stream 1 needs to be raised by 41 °C

This gives rise to a total utility cost over 5 years of £481,000.

).png)

).png)