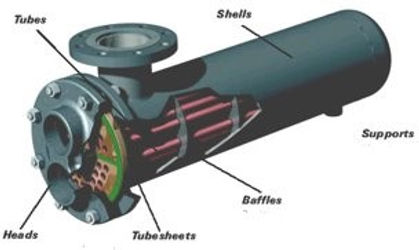

1. SHELL & TUBE

Shell with tubes inside it

1 fluid runs through the tubes

The other fluid runs over the tubes

Heat is tranferred in this way

Set of tubes is a tube bundle

Different types of tubes: plain...

Features

Applicable to a wide range of

pressure and temperature conditions

Widely known most common type of heat exchanger

Big, Expensive maintenance

Subject to flow induced vibrations – may lead to equipment failure

Contains dead/stagnant zones on the sides of the shell which could lead to corrosion issues

2. GASKETED PLATE

Thin corrugated plates fitted with gaskets

Plates compressed into rigid frame

Parallel flow channels with max

turbulance

Fluids enters at top & bottom of exchanger

Fluid flows in alternative channels

Follows counter current principle

Features

High thermal efficiency

Compact design so small quantities of materials are used for heat transfer surface

High performance

Low installation cost

Gasketed design, plates can be easily dismantled, allowing easy and rapid cleaning

Versatile design can easily adjust capacity of heat exchanger by adding or removing plates

Environmentally efficient

Gasketed plates are sealed tight, however these heat exchangers are more prone to leakage than shell and tube

Not efficient for fluids with huge temperature differences, these tend to be used for fluids with minimal/ normal temperature differences

3. SPIRAL

Circular

Two concentric spiral

channels

Each channel is for one fluid

Curved channels

Allows max heat transfer

Small overall unit size

Features

Self cleaning effect, reduces operating costs

Low maintenance cost due to easy access

High heat transfer efficiency, better than shell and tube

Can handle two highly fouling fluids

Each unit is fully drainable

Condensers have virtually no vapour side pressure drop

Column mounting of condensers reduces installation costs

Usually have limitations on the maximum temperature and pressure allowed to reach

Tend to have a lower volumetric flowrate than other types of heat exchangers